Innova

We work to create the future in styrenic products, resins and processed plastics.

In the petrochemical area, we manufacture ethylbenzene (EB) and, from this substance, we obtain styrene monomer (SM), a core product in the economy and feedstock for the resin we manufacture: polystyrene (PS), in all its variations.

In the area of processed plastic products, we manufacture bioriented polypropylene (BOPP) films, polystyrene (PS) and polypropylene (PP) reels, and plastic caps for PET bottles for use with mineral water, juices, and soft drinks.

Where it all Started

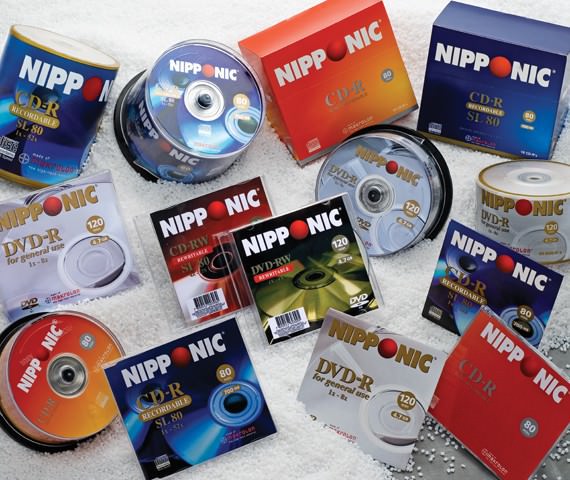

The origins of Innova are to be found in Videolar, a manufacturer of blank and pre-recorded media carriers (VHS magnetic tapes, audio cassettes, floppy disks, pen drives, CDs, DVDs and Blu-Ray discs). Videolar was founded in Caxias do Sul (Rio Grande do Sul) in 1988, establishing itself as the largest media carrier manufacturer in the country, with a verticalized production system acknowledged as unique anywhere in the world, serving practically the entire national market, end-to-end.

The Company made a strategic move in 2002, changing from being the largest Brazilian consumer of polystyrene to becoming a resin manufacturer. Videolar built the first petrochemical plant in the Northern Region of the country, designed to supply materials for its own consumption of VHS and tape cartridges and supplying several factories within the Manaus Pole, including those in the segments of electronics cabinets, school supplies and hygiene items. The foundations had thus been laid for the petrochemical business, which then expanded into processed plastics manufacturing of bioriented polypropylene films (BOPP), polystyrene (PS) and polypropylene (PP) reels, and caps for PET bottles for use with mineral water, juices and soft drinks.

Timeline

Mission

To be a leader in our business segment, by being trustworthy and developing strong ties with customers and employees, assuming a sustainable attitude towards the environment, and ensuring the returns for our shareholders.

Vision

Knowing how to listen, develop and deliver: there is always a clear need.

A leading Company offers solutions.

Values

Committed and transparent conduct;

The ability to adapt;

Totally focused on customer needs.

Industrial plants and headquarters

HEADQUARTERS

HEADQUARTERS

Built-up area: 27,032 m²; total area: 29,999 m²

Av. Tamboré, 25 – Alphaville

06460-000 Alphaville Barueri São Paulo Brazil

Phone: +55 (11) 4197-7000

- Sales and Administration

PLANT I: MANAUS (AMAZONAS)

PLANT I: MANAUS (AMAZONAS)

Built-up area: 64.519 m²; total area: 289.314 m²

Av. Torquato Tapajós, 5555 – Tarumã

69041-025 Manaus Amazonas Brazil

Phone: +55 (92) 3878-9000

- Bioriented polypropylene plastic films (BOPP)

- Polystyrene (PS) and polypropylene (PP) reels

- Closure caps for PET mineral water, juices and soft drinks bottles

PLANT II: TRIUNFO (RIO GRANDE DO SUL)

PLANT II: TRIUNFO (RIO GRANDE DO SUL)

Built-up area: 174,929 m²; total area: 242,000 m²

BR 386, Km 419, P. Petroq. do Sul

95853-000 Triunfo Rio Grande do Sul Brazil

Phone: +55 (51) 3457-5800

- Ethylbenzene (EB)

- Styrene Monomer (SM)

- General Purpose Polystyrene (GPPS)

- High Impact Polystyrene (HIPS)

- Expandable Polystyrene (EPS)

- PS-3D

- Steam and Power Generation Plant

- Styrenics Technology Center

PLANT IV: MANAUS (AMAZONAS)

PLANT IV: MANAUS (AMAZONAS)

Built-up area: 26,904 m²; total area: 67,048 m²

Av. Abiurana, 1616 – Distrito Industrial

69075-010 Manaus Amazonas Brazil

Phone: +55 (92) 2101-7800

- General Purpose Polystyrene (GPPS)

- High Impact Polystyrene (HIPS)

- ECO-PS®